Data Maturity Acceleration Project

GLENCORE Metals faced commercial data issues post SAP go-live which caused problems with procurement.

Glencore Selects Vueterra for New, Global Master Data Project

Mining giant Glencore Metals selected Vueterra as the primary supplier of master data solution services across more than 90 global mine sites.

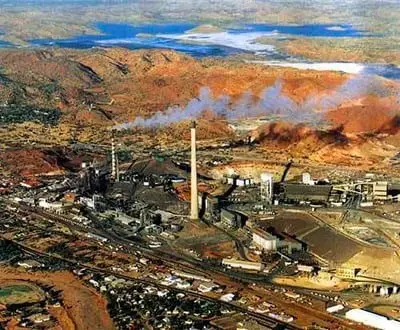

The Brisbane-based supply-chain data specialists, Vueterra was selected by Glencore following a SAP S/4HANA project delivered at Mount Isa Mines in Queensland.

The initial project was required to rectify data issues that had significantly delayed the procurement processes at Glencore’s Mount Isa Mines.

Investigations by Vueterra at Mount Isa Mines uncovered poor supplier data. A recent ERP implementation had disrupted previous workarounds which allowed teams to previously side-step long held problematic data.

The introduction of SAP emphasised the data issues requiring a heavy reliance on manual purchase order conversion, queries and updates that extended lead times significantly.

During the preliminary health-check, data was found to be misaligned without appropriate classification or method of management to control procurement practices.

“We always start projects with a data health- check,” said Vueterra CEO Jeff Warren, who headed the project.

“It is an important part of the process on multiple fronts. At Glencore for instance, by demonstrating issues at a macro level, we could explain to the leadership team how poor data standards are impacting the business, and how important data is” he said.

“But it also helps us to take a holistic view of supply-chain data to ensure our team doesn’t risk missing anything and accurately identify the root cause of issues."

"And finally, we also use the first data set to compare the ‘after’ state of data, to measure improvement,” he said.

Results

“Overnight, our purchase order automation rose by 30 percent in 2 weeks after the data upload,” said Glencore’s Commercial Manager, Clemens Engelbrecht.

Vueterra’s continual project analysis revealed that the 66 suppliers and 60,000 records scored a pass rate of 54%. Outline Agreement and repairable component data scored pass rates of 29% and 83% respectively.

The cause: incorrect or redundant data, misalignment of master data settings, and data records not created to facilitate the appropriate SAP automation functionality.

Vueterra’s team also provided specialist consulting to propose valuable improvements to manage supersessions, classify inventory, and improve P2P processes to boost operational value for front-line staff and supplier synchronisation.

Glencore’s Mount Isa Mines group have gained insights into SAP and how to extract continuous value from the system.

“We’re thrilled to have won the shootout against one of the big four consulting firms to start with,” said Jeff Warren.

“And then, to see automation improve by 30 percent due to our work is the kind of stuff that makes me glad I did step out and start this business years ago,” he said.

“Being able to apply years of SAP and data operational experience to these projects,

we’re proud to be data specialists, rather than generalists in everything,” he said.

The Solution

Since the Mount Isa Mines project, Vueterra have adapted their internal tools to further improve project quality, value, and repeatability.

“Mount Isa Mines has been a successful pilot and during our quality review of the project we identified opportunities to automate the process further and establish more accountability,” says Jeff

“We realised where most of our time sink was during the project and wanted to spend more quality time with suppliers. We are now utilising Jira Service Management to centralise our communication, essentially removing emails, assigning accountability to each project stage, and improved our Alteryx analysis to deep dive into maintenance data to unify alignment actions where duplications etc. are involved.”

“Data action and reporting is also another key, and we continue to build out our dashboard reporting and exception reports. It’s essential for leadership to understand the state of the data without knowing the detail. We deliver the detail to the users via the Exception reporting directly from Alteryx furthering the focus on automation.”

About Vueterra

Vueterra is a specialist in supply chain optimisation with focus on the Heavy, Mining and Government Industries.

Our work is proven to deliver higher service levels and lower costs for clients through solid data governance, procurement best-practice and comprehensive continued improvement programs.

At Vueterra, it’s about getting a view of your business from the ground; gaining insight into the root cause of problems to efficiently address your priority issues, and provide long-term value to the business with custom services built upon our real-world experience.